XIAMEN ROBOSIGHT TECHNOLOGY CO., LTD

Booth No. A276 Web:www.robo-sight.com

Company Profile

Xiamen Robosight Technology Co.,Ltd. was established in September 2014, dedicated to providing intelligent equipment research and development, production, and services for high-tech manufacturing enterprises. The advantages of robosight are reflected in its strong interdisciplinary integration ability, possessing high-level technology in fields such as software, mechanics, optics, mechatronics, and electronics. We have obtained multiple honors such as national high-tech, technological giant, specialized and innovative, and have also passed ISO9001 and ISO14001 system certifications. Since its establishment, we have continuously focused on the research and development, production, and service of equipment for high-tech manufacturing enterprises. Based on the demand for automation, intelligence, and intelligence for high-tech manufacturing enterprises, we aim to create a full process service from research and development, production, sales, product solution design, and after-sales operation and maintenance, and achieve fully automated, comprehensive, low-cost, and efficient management for customers. The team of robosight has a size of over 100 people, including over 60 software development, mechanical design, visual development, and electrical R&D engineers, forming over a hundred intellectual property rights. It has the ability to independently research and develop innovation, software and hardware development and integration, and provides one-stop solutions for industrial manufacturing enterprises. It is an intelligent equipment overall solution provider with a complete marketing system, technical support system, and operation system. Exhibits

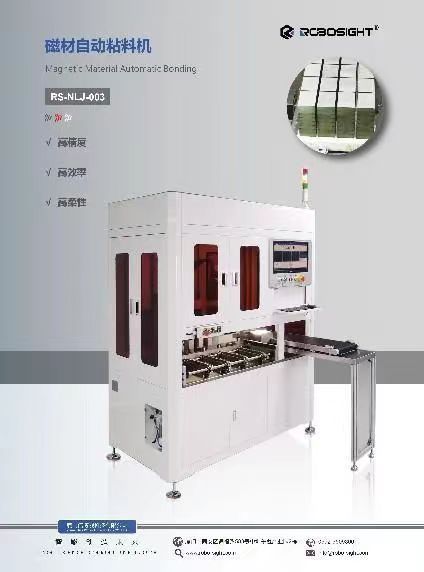

1. Magnetic Material Automatic Bonding Magnetic material automatic bonding machine is used for the bonding process in the first, second or third sequence processing of magnetic material. It can be compatible with square and tile products. Equipped with FANUC robot and Machine vision, the bonding accuracy reaches 0.1mm,which can achieve the glue, labor and raw materials saving.

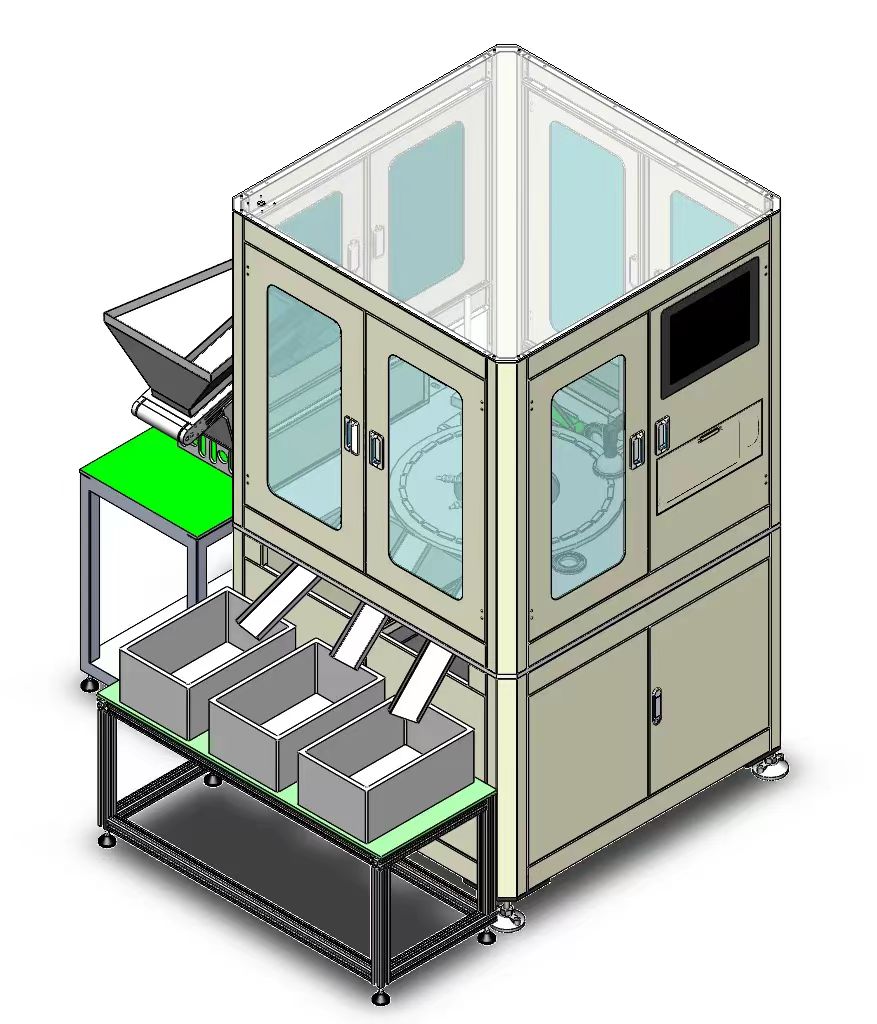

2. Magnetic sheet Arranging(Screen Printing) Magnetic sheet arranging machine is used for placing the products in order in the tray in the production of screen-printing process. It can be compatible with products:cuboid (length - width) >1.5mm) Fixture: 460*250 ±0.2mm;

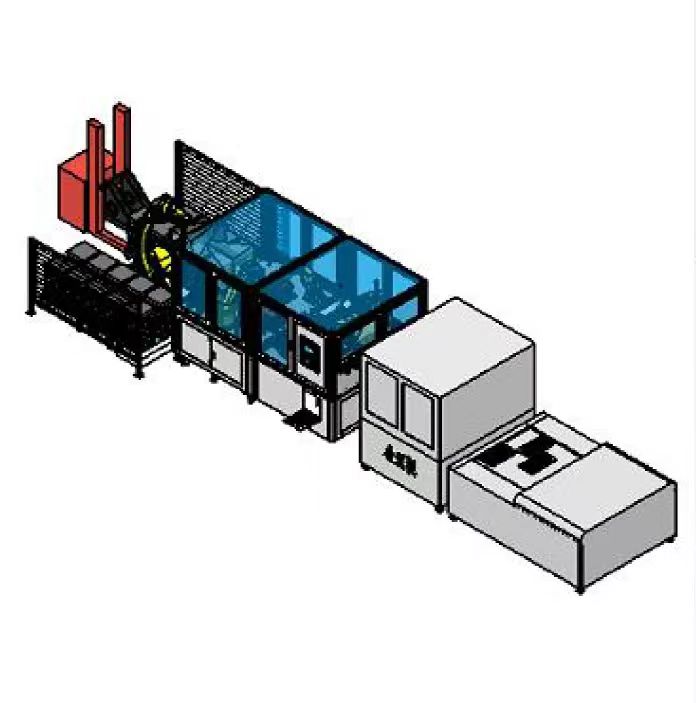

3.Magnet Steel Unloading & Boxing & Stacking Machine(Screen Printing) After the screen-printing line, the machine is used to automatically remove the trays from the line, pick the magnetic sheets, and separate them, then place them in the graphite boxes according to the requirements, and finally stack the boxes on the special furnace tray or pallet to replace manual operation, aims to reduces labor costs and manual strength.

4.Magnet Steel Appearance Detection Machine The machine is used for the sorting of the outer dimension and the appearance defects of the magnetic steels. The rotating mechanism makes the magnetic multi-faceted continuous inspection by using high-definition cameras and learning algorithms to automatically identify all kinds of defects. It can be compatible with a variety of magnetic sheet sizes, and can complete automatic feeding, automatic detection, automatic sorting, and other functions.

5.Magnetic Orientation Detector The magnetic material orientation detector can detect the correctness of the orientation direction of the magnetic material and judge the correctness of the orientation in the magnetic material processing and production, and detect the correctness of the magnetic material placement direction in the subsequent process.

|