深圳市智哥机器人系统有限公司 Shenzhen Zege Robot System Co., Ltd. 展位号:D016 展出产品:柔性振动盘、伺服电动缸、集成伺服电动缸、柔性上料工作站等 网址:www.zege-motor.com

深圳市智哥机器人系统有限公司是“专精特新”小巨人企业——深圳市鸿栢科技实业有限公司旗下子公司,成立于2017年7月,注册资本1000万元,拥有十三项软件著作专利,专业从事视觉焊弧机器人、自动化柔性上下料、高精伺服电动缸设备研发与生产的高新技术企业。

Shenzhen Zege Robot System Co., Ltd. is a subsidiary of Shenzhen Hongbai Technology Industry Co., Ltd., a "specialized, refined, and innovative" small giant enterprise. Founded in July 2017, with a registered capital of 10 million yuan, it has thirteen software copyright patents and is a high-tech enterprise specializing in the research and development and production of visual arc welding robots, automated flexible loading and unloading, and high-precision servo electric cylinder equipment. Flexible vibration disc

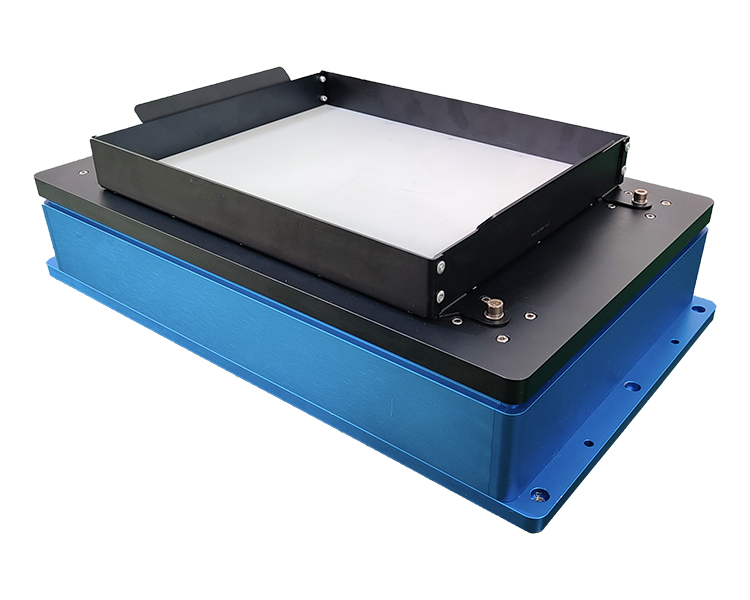

智哥柔性振动盘适用于工业自动化生产中99%的小型零部件散料排列上料,包括异形件及精细易损伤零部件,多达11种运动模式,覆盖视觉上料应用所有振动需要;快速切换生产品种无需更换硬件结构,程序一键切换生产品种。

Zege Flexible Vibration Disk is suitable for arranging and loading 99% of small components in industrial automation production, including irregular parts and fine and easily damaged parts, with up to 11 motion modes, covering all vibration needs of visual loading applications; Quickly switch production varieties without changing hardware structure, the program switches production varieties with one click.

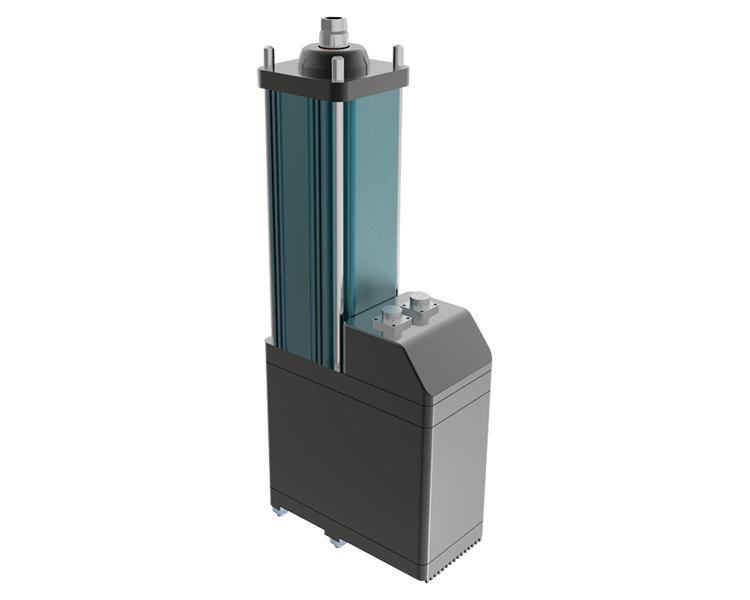

智哥中空电动缸采用伺服电机与行星滚柱丝杠一体化的设计方法,伺服电机转子的旋转运动直接通过滚柱行星分布在主丝杠周围,将电机的旋转运动转化为主轴或螺母的直线运动,可根据客户的需要进行个性化定制服务。

Zege The hollow electric cylinder adopts an integrated design method of servo motor and planetary roller screw. The rotational motion of the servo motor rotor is directly distributed around the main screw through the roller planet, transforming the rotational motion of the motor into linear motion of the spindle or nut. Personalized customized services can be provided according to customer needs. Integrated servo electric cylinder

针对现场空间狭小、传统气缸、液压缸精度差而研发,内置无刷伺服电机与滚柱丝杆传动结构融为一体,伺服电机转子的旋转运动直接通过滚柱行星分布在主丝杆周围,避免弹性变形、磨损、间隙、发热等因素造成的传动误差。

Developed for the narrow on-site space and poor accuracy of traditional cylinders and hydraulic cylinders, the built-in brushless servo motor is integrated with the roller screw transmission structure. The rotational motion of the servo motor rotor is directly distributed around the main screw through the roller planet, avoiding transmission errors caused by elastic deformation, wear, clearance, heating, and other factors. Flexible feeding system

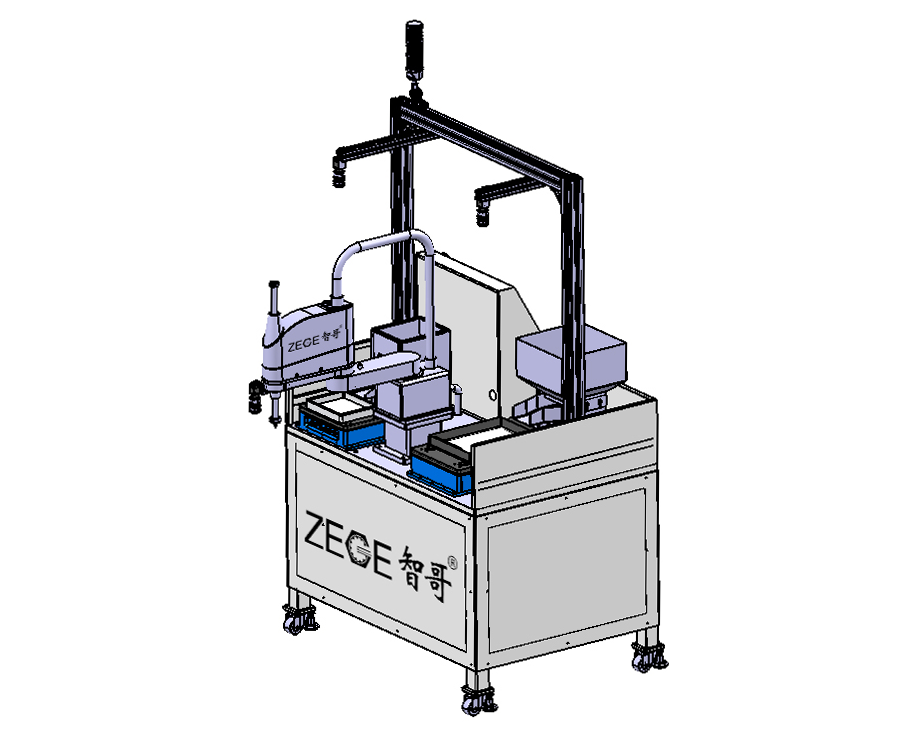

智哥柔性上料工作站通过柔性振动盘和2D/3D视觉定位装置配合PC的操作运行,搭配SCARA机械手,以更高的定位精度解决传统振动盘无法供料的难题,填补微小产品、精密产品的供料空白,实现全自动上下料并加工。

Zege Flexible Feeding system uses flexible vibration discs and 2D/3D visual positioning devices in conjunction with PC operation, coupled with SCARA robotic arms, to solve the problem of traditional vibration discs being unable to supply materials with higher positioning accuracy, fill the supply gap of small and precision products, and achieve fully automatic loading and unloading and processing.

|