宁波吉兆电气科技有限公司

Ningbo Jizhao Electrical Technology Co., Ltd.

展位号:2150

展出产品:吸尘器、电主轴、

氢燃料电池空压机、无人机、轴向电机等

邮箱:wangkunming@nbjizhao.com

网址:www.nbjizhao.com

公司简介

宁波吉兆电气科技有限公司为客户提供优质的产品和优良的服务。公司拥有专业研发团队,与高校、研究单位建立了长期合作关系,公司已建成国内外首套非晶定子铁心量产线,产品主要包括非晶驱动电机、电机控制系统、非晶高速电机/电主轴和医疗/军用非晶电机等及其关键零部件。

我们始终坚持自主创新,创立之初便以“高效、节能、环保”为依托;以“科技、创新、自主”为核心动力;竭诚为全社会奉献“小体积、高效率、高功密、高频高速”的超高效节能非晶电机,为节能减排贡献力量。

Ningbo Jizhao Electric Technology Co., Ltd. provides customers with high quality products and excellent services. The company has a professional R & D team, and has established long-term cooperative relations with universities and research units. The company has built the first batch production line of amorphous stator core at home and abroad, and its products mainly include amorphous drive motor, motor control system, amorphous high-speed motor / motorized spindle, medical / military amorphous motor and its key parts.

We always adhere to independent innovation, and at the beginning of its establishment, we relied on "high efficiency, energy saving and environmental protection"; Take "science and technology, innovation, independence" as the core power; Dedicated to the whole society "small size, high efficiency, high power density, high frequency and high speed" super efficient energy-saving amorphous motor, contribute to energy saving and emission reduction.

部分展品

1、吸尘器

Vacuum cleaner

产品介绍

采用非晶材料代替硅钢作为电机的定子铁心部分、利用非晶材料在高频下仍然具备高饱和磁感、低损耗与高磁密的特点,吸尘器设计功率在100-1000瓦、转速12000r/min、效率能提高6-10%。

Amorphous material is used to replace silicon steel as the stator core of the motor. The amorphous material still has the characteristics of high saturation magnetic induction, low loss and high magnetic density at high frequency. The design power of the vacuum cleaner is 100-1000w, the speed is 12000r / min, and the efficiency can be increased by 6-10%

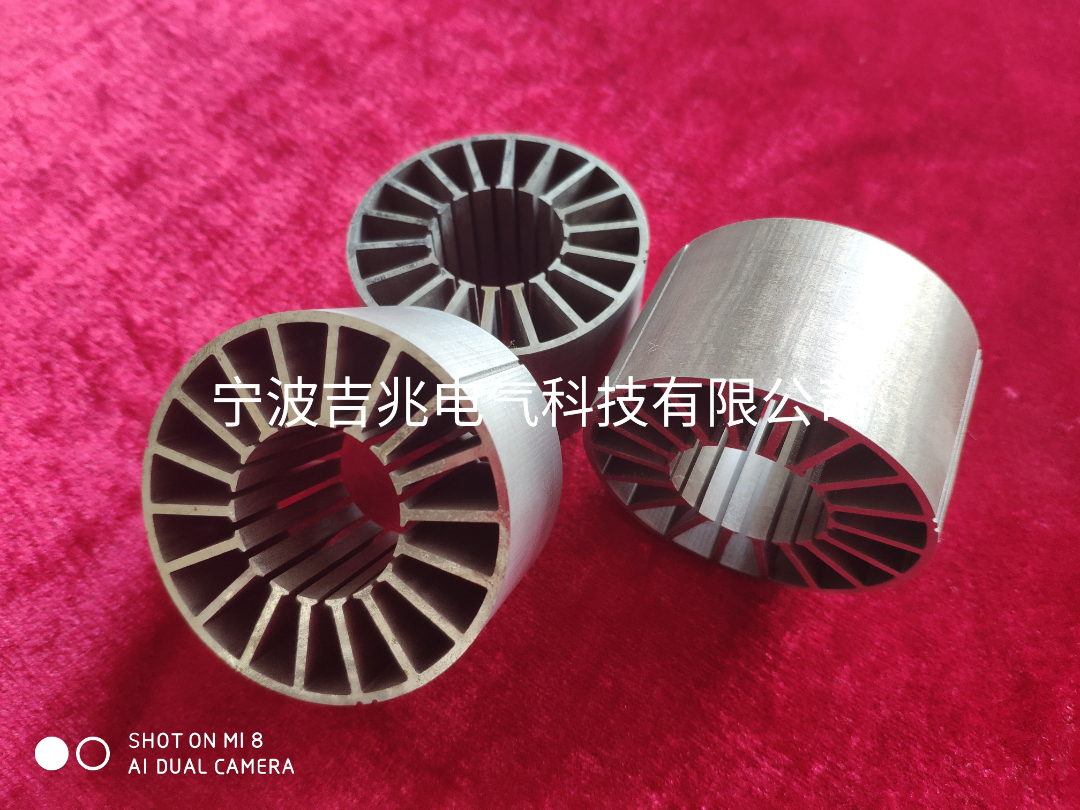

2、电主轴、氢燃料电池空压机

Motorized spindle, hydrogen fuel cell air compressor

产品介绍

应用于军事、工业、环保等高速电机/电主轴领域。

高效、节能、重量轻、体积小、无噪音的电机的市场应用潜力巨大,特别是转速在30000r/min~120000r/min的高速主轴电机等领域。本公司新型非晶产品可以突破矽钢片的频率限制做到高频控制下的高转速大功率。使用新型非晶材料的高速电机/电主轴支持:转速3~20万转,1~200kW的高频大功率电机。

It is used in military, industrial, environmental protection and other fields of high-speed motor / motorized spindle.

High efficiency, energy saving, light weight, small volume, no noise motor has great market application potential, especially in the field of high-speed spindle motor with speed of 30000r / min ~ 120000r / min. The company's new amorphous products can break through the frequency limit of silicon steel sheet and achieve high speed and high power under high frequency control. High speed motor / motorized spindle support with new amorphous material: high frequency and high power motor with speed of 30000-200000 rpm and 1-200kw.

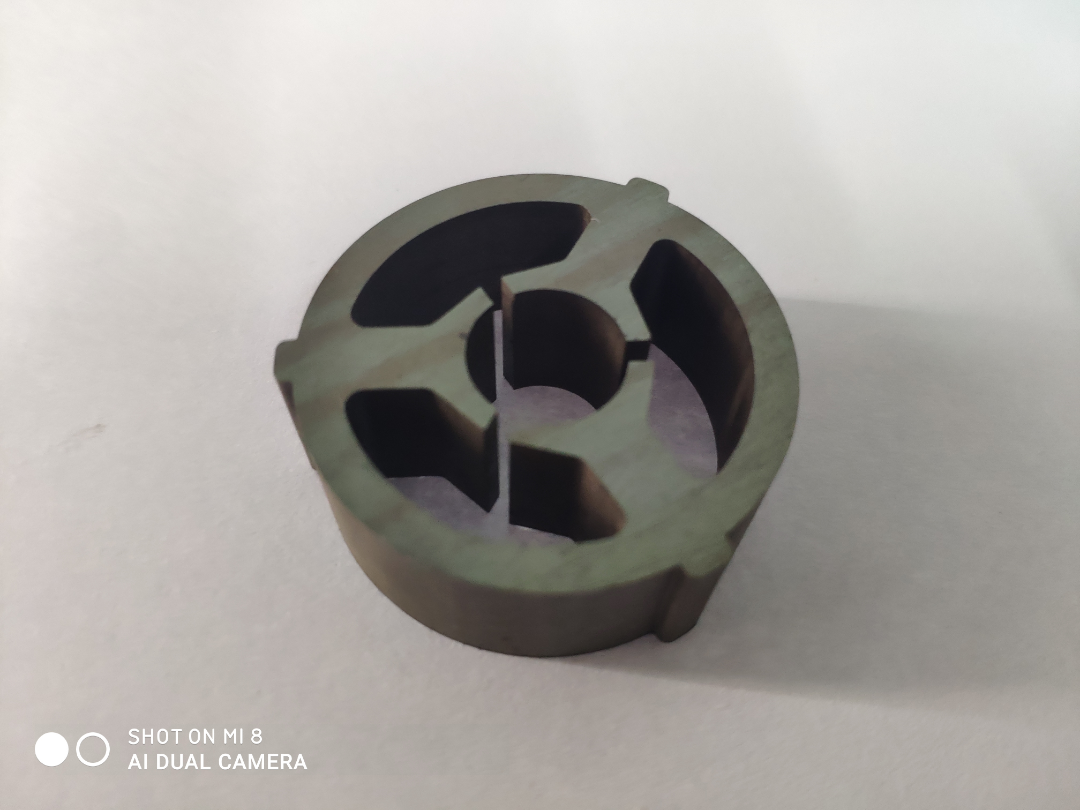

3、无人机

UAV

产品介绍

采用非晶材料代替硅钢作为电机的定子铁心部分、利用非晶材料在高频下仍然具备高饱和磁感、低损耗与高磁密的特点,增加永磁电机的定子极数,从而在相同功率与转速下获得更小的体积、能耗与更高的效率、扭矩。

Amorphous material is used to replace silicon steel as the stator core of the motor. The amorphous material still has the characteristics of high saturation magnetic induction, low loss and high flux density at high frequency, so as to increase the number of stator poles of permanent magnet motor, so as to obtain smaller volume, energy consumption and higher efficiency and torque at the same power and speed.

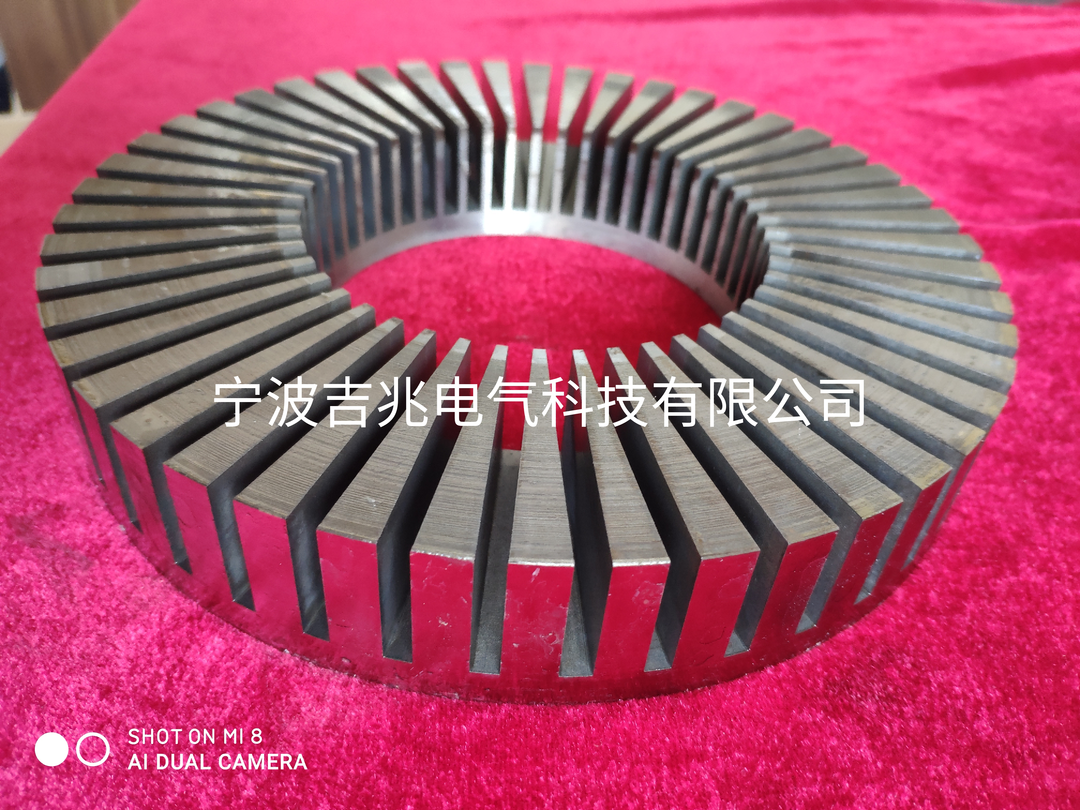

4、轴向电机

Axial motor

产品介绍

应用于新能源汽车轮毂、驱动、启发、增程领域。

新能源汽车对电机的体积、重量、功率密度等都有很高的要求,所以大多电机设计成200-1600HZ的控制频率,而目前基于硅钢设计的电机普遍发热严重,给冷却系统造成巨大压力,也降低了整套动力/发电系统运行可靠性。 而新型非晶材料在高频控制下的低铁损(相当于硅钢的1/8-1/10) 特性能够大幅度的降低电机温升,同时非晶电机具备体积小、重量轻、效率高、功率密度高、噪音小等优点,是当前解决新能源汽车电机温升的优良方案之一。经过优化设计的新型非晶电机也将在一定的程度上优化驱动/发电系统,提高空间利用率、整机运行效率。

It is used in the fields of hub, drive, inspiration and range extension of new energy vehicles.

New energy vehicles have high requirements for motor volume, weight, power density, etc., so most of the motors are designed with 200-1600hz control frequency. At present, the motors based on silicon steel are generally hot, which causes great pressure on the cooling system and reduces the operation reliability of the whole power / power generation system. At the same time, the amorphous motor has the advantages of small volume, light weight, high efficiency, high power density, low noise and so on, which is one of the excellent solutions to solve the temperature rise of new energy vehicle motor. The optimized design of the new amorphous motor will also optimize the drive / power generation system to a certain extent, improve the space utilization and the operation efficiency of the whole machine.