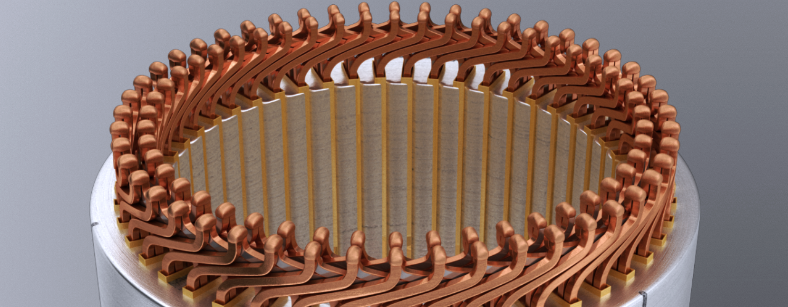

Within the electric motors used in every electric vehicle, we find a key component in the design of high-performance EV motors: hairpins. Hairpins are thin metal strips that are used in the winding of stator in electric motors to reduce the resistance and increase the conductivity of the winding. This results in improved efficiency and higher power density of the motor.

Hairpins not only improve efficiency, they also help reduce the overall size and weight of the motor. This is because they allow for a more compact winding design, which means that fewer materials are needed to produce the same amount of power. The use of hairpins can also lead to improved thermal performance, as the reduced resistance results in lower heating of the winding and the surrounding components.

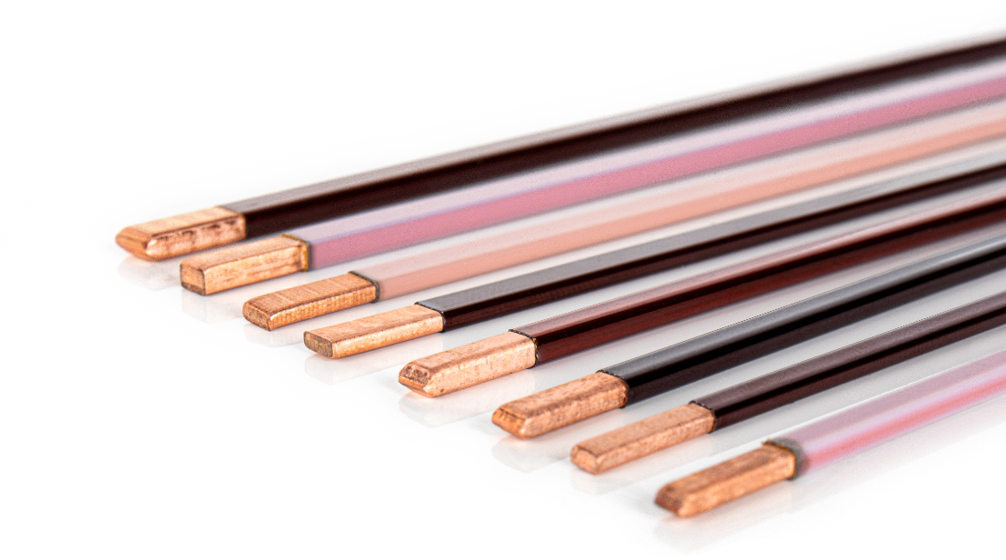

Various materials can be used in hairpin manufacturing, including copper and aluminum, with copper being the most common due to its high conductivity. Hairpins are covered with an insulating material, such as polyamdimid, polyetheretherketon, polyimid, polyurethane or polyesterimide. It is necessary to strip a part of the insulation before hairpins can be welded together.

The Advantages of Using Fiber Laser for Hairpin Applications

As the demand for electric vehicles continues to rise, EV manufacturers are challenged to produce hairpin motors with new design specifications which require improved methods for insulation stripping and welding of conductors. IPG fiber lasers offer advantages that conventional methods doní»t for both steps in the electric motor manufacturing process.

Hairpin Stripping

Before welding hairpins together, it is necessary to remove the insulating layer. Typical requirements for this include high process velocity, clean edge (residue-free), no thermal damage to the insulating material and no oxidation of surface.

The process usually consists in the ablation of an area of around 8 to 12 mm, removing the insulating material to reveal the copper, which will later me welded to other hairpin. Compared to other technologies, laser hairpin stripping is an easy to use, contact-free method, that offers:

í˝Defined edge í˝Residue-free í˝No thermal damage of insulation í˝No oxidation of surface í˝No tool wear í˝No reduction of cross section These features make fiber laser the best option for hairpin stripping, as it meets all the requirements that make the process faster and of higher quality. Solutions for insulation stripping are generally pulsed lasers combined with scanners that are integrated into the motor assembly tools.

Hairpin Welding

Typical requirements for hairpin welding include electrical conductivity of the weld seam, homogeneous weld cross section, low spatter, no pores, define edge and low thermal input. All these requirements are covered by IPG fiber laser solutions. Additionally, depending on the customer needs, the weld can either be a ball weld or a butt weld.

For hairpin welding, solutions may be either individual lasers or the combined Integrated Laser Welding System (ILWS), which includes a programmed controller and vision alignment system to make tooling and line integration even easier. The IPG scanners not only allow to locate all the pins on a single scan field, eliminating part motion steps, but are capable of pre-scanning in order to verify and, if necessary, correct pin position to ensure flawless welding.

Fiber Lasers: The Best Solution for EV Hairpin Motor Applications

Hairpin Welding

Typical requirements for hairpin welding include electrical conductivity of the weld seam, homogeneous weld cross section, low spatter, no pores, define edge and low thermal input. All these requirements are covered by IPG fiber laser solutions. Additionally, depending on the customer needs, the weld can either be a ball weld or a butt weld. For hairpin welding, solutions may be either individual lasers or the combined Integrated Laser Welding System (ILWS), which includes a programmed controller and vision alignment system to make tooling and line integration even easier. The IPG scanners not only allow to locate all the pins on a single scan field, eliminating part motion steps, but are capable of pre-scanning in order to verify and, if necessary, correct pin position to ensure flawless welding.

Source: IPG Photonics

IPG Photonics: The Experts In E-Mobility Laser Solutions

Whether you need to demonstrate laser processing feasibility with your parts, or just want to bounce design and implementation ideas about your e-mobility manufacturing processes off an experienced laser engineer, give us a call. IPG is the world leader of fiber laser technology and experts in materials processing. We apply this expertise to our e-mobility solutions, with the sole purpose of offering manufacturers the necessary tools through laser processing to obtain the best e-mobility application results. Learn more about the entire scope of E-Mobility solutions that IPG offers here.

|