Tonghe Precision Mold Co., Ltd Booth No. 2564

www.tongheltd.com

Company Profile

Tonghe Precision Mold Co., Ltd. is a powerful manufacturer specializing in the design, manufacturing, production, sales and service of progressive tooling for all kinds of motor laminations. It manufactures capable tooling with auto-stacked, auto-skewed and rotary (indexing) rotors and stators in processed cores or loose laminations, and has rich experience especially in design and manufacturing of progressive tooling for stepper motor cores. Our customers include overseas and Chinese funded enterprises. Providing high quality, high efficiency and high lifetime progressive tooling is our mission, and our commitment to our customers. The company is located in Wujin District, Changzhou City, easily accessible as it is close to the Shanghai-Wuhan Expressway, the 312 National Highway and the Changzhou Ring Elevated Highway. Our servo motor hinge core progressive tooling are well-known in China. We have domestic partners all over the country, and are receiving more and more orders from foreign customers. Our products are exported to the United States, Japan, South Korea, Italy, India, Brazil, to name just a few, and are highly recognized by both domestic and foreign customers. We specialize in the design and production of progressive tooling for all kinds of motor stator and rotors. The manufacturing accuracy of the main parts of the tooling reaches as high as 2 ¦Ìm and the pitch precision can be controlled within 5 ¦Ìm. The tool life attains to above 150 million strokes. Our tooling realize multiple functions such as auto pressure charging, auto stacking, step holes punching, auto skewing, and auto rotation. We can also make single-row or multi-row tooling according to customer requirement. The fast tooling production lead time is way beyond our peers.

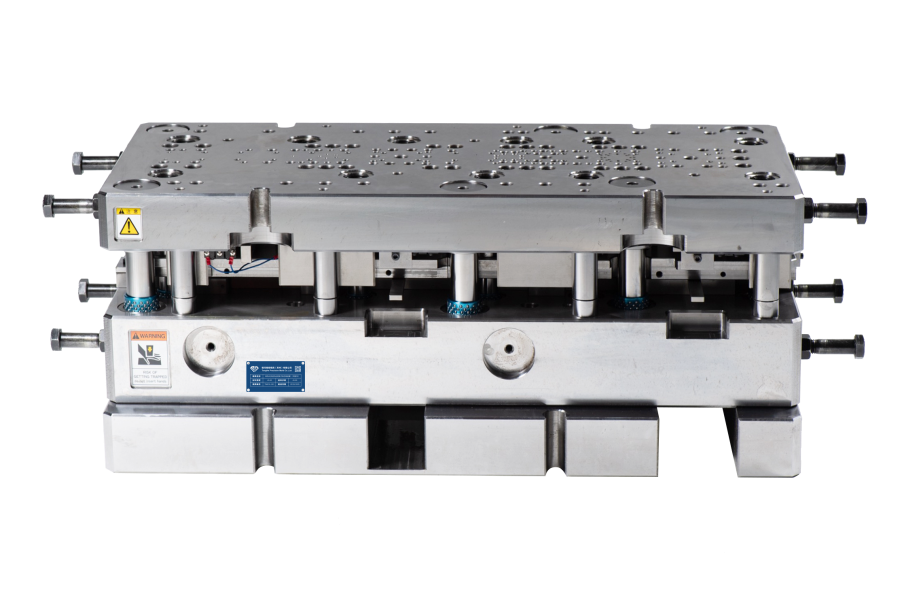

Exhibits 1. Mould samples

The manufacturing accuracy of the main parts of the tooling reaches as high as 2 ¦Ìm and the pitch precision can be controlled within 5¦Ìm. The tool life attains to above 150 million strokes. Our tooling realize multiple functions such as auto pressure charging, auto stacking, step holes punching, auto skewing, and auto rotation.

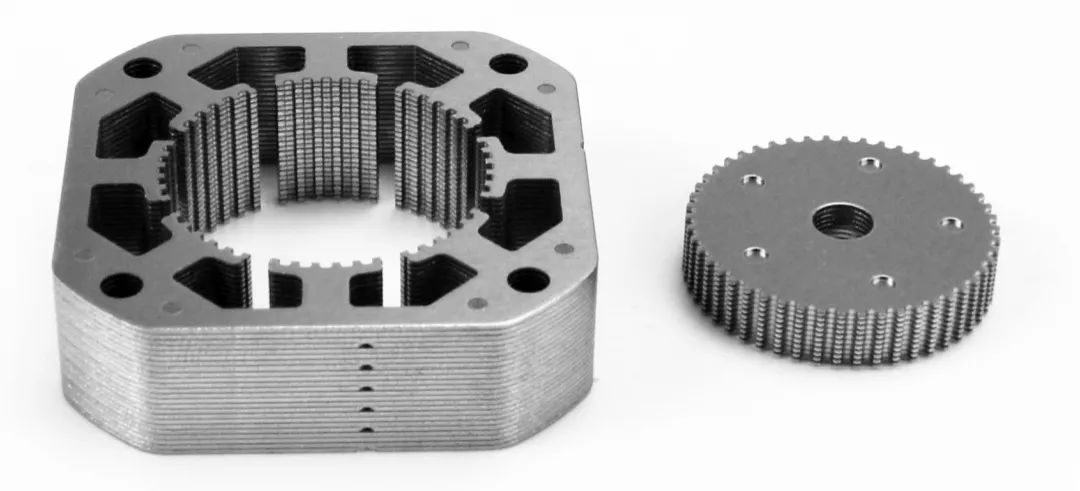

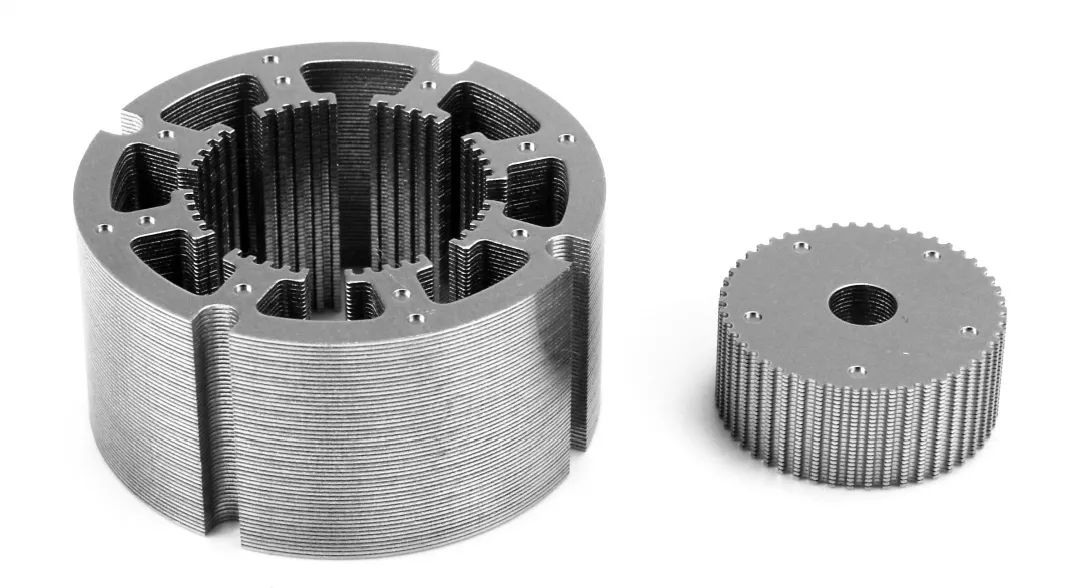

2. Stepping motor_42 stator core

Product shape 42.2 ¡Á 42.2-L43. 90¡ã rotation of stator. The perpendicularity is 0.08 and the inclination is 0.1.

3. Stepping motor_57 stator circular core

Product shape 56.2 ¡Á 56.2-L89. 90¡ã rotation of stator. The inclination is 0.15 and the flatness is 0.15.

Click here to pre-register to Exhibit Click here to pre-register to Visit

|